LEDs

12 Volt LED Light Engine - DynaSquare

12 Volt LED Strip Light Engine - Duo

12V 6W LED Light Engine - Draco

24 Volt LED Strip Light Engine - Duo

Antares Cree XP-G3 LED Light Module by LUXdrive

Centaurus High-Power Cree LED Light Module by LUXdrive

Cree CXB 1310 High Density LED Array

Cree CXB 1520 High Density LED Array

Cree XLamp Element G (XE-G) Pulsar LED Star

Cree XLamp XHP35 High Density LED Star

Cree Xlamp XM-L2 High Power LEDs

Cree XLamp XP-E High Power LED Star

Cree XLamp XP-E2 Color High Power LED Star

Cree XLamp XP-E2 White High Power LED Star

Cree XLamp XP-G2 High Power LED Star

Cree XLamp XP-L High Density LED Star

Cree XLamp XT-E Royal-Blue LED(s)

Cree XLamp XT-E White LEDs

Cree XML - RGBW Star LED

Cree XPE2 - RGB High Power LED

Cree XPG - QuadPod 4-Up Cool-White High Power LED

Custom 3-Up Cree High Power LED

Custom 3-Up Luxeon High Power LED

Dynamic Tunable White LED Strip Light - 24V High-Output Adjustable CCT LED Series

LED Binning Explained

| A | Flux Bin |

| B | Color Bin |

| C | Forward Voltage Bin |

In the manufacturing of LEDs there is a variation of performance around the average values given in the technical data sheets. This means that in the manufacturing process the color, flux (brightness), and even forward voltage can be different from production run to production run. For this reason, manufacturers bin the LED components for these three areas in order to tell specifically what the characteristics will be and so that applications that need all the same LEDs make sure to purchase diodes that are of the same bin.

The manufacturers data sheets (linked at the bottom of every LED product page) will show you what the bin number means so you can search for bins that are just right for you. Here at LEDSupply we try to pick the bins with the highest flux and lowest forward voltage as this will make sure they are the most efficient possible. We always make it a priority to try and provide customers with the same binned LEDs so that there are no variations from diode to diode.

LED emitters (diodes) are labeled using a three to four digit alphanumeric code (CAT code) showing the bin values for emitters packaged on a single reel. All emitters packaged within a reel are of the same 3-variable bin combination. To the right is an example of the CAT code layout.

| Incandescent Wattage | Lumens |

| 25W | 230-270 |

| 40W | 440-460 |

| 60W | 800-850 |

| 100W | 1600 |

(A) Flux Bin - LED Brightness

LEDs are the brightest lighting solution out there. In terms of brightness, they are measured in Lumens. A lumen is a scientific unit measuring luminous flux or the total amount of visible light from a source. The amount of light (Lumens) you can get out of a single LED depends on how much current you supply to it, this is measured in milliamps (mA) or amps (A). To the right you can see Lumens in the sense of 25, 40, 60 and 100 watt incandescent bulbs, in-case you want to switch to LEDs while keeping a similar amount of Lumens. We also have a breakdown of the LEDs we offer in terms of brightness right here.

(B) Color Bin - Correlated Color Temperature & Color Wavelengths

LEDs allow for a variety of different color whites. Correlated Color Temperature (CCT) is the process of creating different white light at different temperatures. Color temperature is specified in degrees Kelvin (K), which is a temperature scale in which zero occurs at absolute zero and each degree equals one Kelvin. The lower temperatures from 2,500K to 3,500K tend to be a warmer white, like what we are accustomed to for in-home lighting. Neutral White is around 4000K to 4500K whereas the higher temps 5,000K+ are the cool whites.

LEDs allow for a variety of different color whites. Correlated Color Temperature (CCT) is the process of creating different white light at different temperatures. Color temperature is specified in degrees Kelvin (K), which is a temperature scale in which zero occurs at absolute zero and each degree equals one Kelvin. The lower temperatures from 2,500K to 3,500K tend to be a warmer white, like what we are accustomed to for in-home lighting. Neutral White is around 4000K to 4500K whereas the higher temps 5,000K+ are the cool whites.

LEDs are also great in a variety of colors. What changes the colors is the wavelength in nanometers (nm). See our table below for what colors are made from which wavelengths.

| Color | UV-C | UV-B | UV-A | Violet | Royal-Blue | Blue | Cyan | Green | Amber | Red-Orange | Red | Deep-Red | IR-A |

| nm | 100-280 | 280-315 | 315-400 | 400-440 | 440-460 | 460-490 | 490-520 | 520-580 | 580-590 | 590-617 | 617-627 | 627-670 | 800-1400 |

(C) LED Forward Voltage & Powering LEDs

LEDs are unlike other traditional lights where higher voltages produce brighter light. This is important to know when working with LEDs as most power supplies are made to regulate voltage, not current. Just connecting an LED directly to a standard DC voltage regulated power supply will destroy the diode, as the power supply will provide way more current than what it is rated for as current is not regulated by the power supply.

This is why you need a constant current LED driver between the DC power supply and your LED. The driver then regulates current to the circuit and is never allowed to exceed the maximum current rating of the LED. All you have to do is find the driver that will provide your LEDs with the current they are best run at, this is easy to find by looking at our product pages. In terms of the power supply, the output voltage needs to be at least a few volts higher than the forward voltage rating of the LED(s) you wish to run.

Understanding All Types of LEDs

LEDs are available from us in a large variety of shapes and sizes for a plethora of different applications, sometimes making the selection process a daunting task. To assist in understanding our LED products and how they can be applied to your specific lighting application, we published a comprehensive guide to help you make the switch to LEDs.

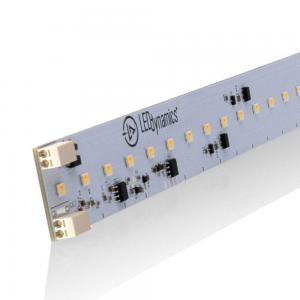

MCPCB: Metal Core Printed Circuit Board. For ease of use, surface mount LEDs are permanently secured 're-flowed' onto a printed circuit board, which is insulated and contains conductive tracks for circuit connections; the printed circuit board is on a metal core heatsink.

Re-Flow LED Soldering: Surface mount LEDs are temporarily combined with a thin mask of solder paste to contact pads on a MCPCB and conveyed through a re-flow oven with controlled heat, melting the solder, and permanently attaching the LEDs.

1-Up or 3-Up Star LED: An LED Star with either 1 or 3 LEDs. The LEDs on the 3-Up star are connected in-series via a zero ohm resistor (jumper).

Lumens: A measurement of the total amount of visible light emitted from a light source.

Forward Voltage: The voltage at which current starts to flow in the normal conducting direction.

HB LED: High-Brightness LED with minimum drive currents of 350mA.

COB LED: Chip On Board LED. Also referred to as high-density (HD) arrays, where hundreds of die are packed into the light emitting surface (LES).

,

Manufacturer

,

Manufacturer